Slurry technology, biogas and waste water components in stainless steel

Your satisfaction is our goal. We are specialized in the design, manufacture and assembly of high-quality stainless steel products. Our broad range of products consists of stainless steel tanks, pumps, agitators and separators for application in agriculture (slurry technology and biogas) as well as in waste water treatment. All products made by Stallkamp are manufactured with own machinery and tools. This is why Stallkamp stands for quality " Made in Germany". Every single part is produced inhouse to ensure highest quality. Make use of this advantage!

Slurry tank or sewage sludge collector? Our tanks are multitalents!

Our products can be applied in various areas. In the agricultural sector they are used as slurry storage or manure tanks. Moreover, they are applied as digesters with insulation and heating, digestate storage or buffer storage for the fermentation process on biogas plants. In the area of wastewater treatment we build collectors for waste water, waste water reactors and various tanks for waste water treatment plants as well as special tanks for glycerin, whey and other process water.

From rotary lobe pump to submersible motor pump - we have a broad pump portfolio!

In terms of pumps, we are specialised in slurry pumps. With submersible pumps, displacement pumps and long shaft pumps, we can offer a broad portfolio for the farming sector. Submersible pumps can be differentiated in submersible motor pumps and submersible motor high pressure pumps. With regard to displacement pumps, the portfolio covers rotary lobe pumps as well as eccentric screw pumps. The pumps are used to pump slurry from and to reception pits of the sheds, final storage tanks, slurry canals etc. On biogas plants they pump biomass to different fermentation processes. Besides, they are applied to pump sewage sludge or industrial waste water.

Submersible motor mixer from Stallkamp - worldwide approved

The mixers from Stallkamp are running in countless biogas plants worldwide to mix up the biomass. But they are as reliable as in AD plants in the agricultural sector where the slurry mixers are installed in manure storage tanks, slurry reception pits or slurry canal systems. For application in industrial plants or on waste water plants with aggressive substances, we developed a full stainless steel agitator to prevent from corrosion. The agitator portfolio offers slow mixers, strong mixers and stream generating mixers.

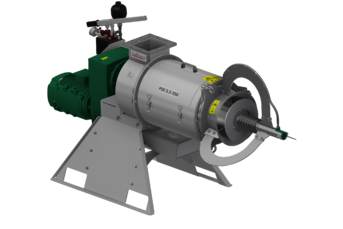

Separation of manure - our separator has crucial advantages

Separation of manure has different reasons. Some operators want to improve the transportability of the manure and others use it to produce bedding material. The separator from Stallkamp reaches very high contents of dry matter in the solids which makes the separator useful for the production of bedding material. With the hydraulic ball head it is possible to adjust the desired degree of dry matter. Whether it separates digestate or bedding material, the operator decides the degree of dry matter. Our separators are also applied in industrial food and beverage production and waste water treatment plants. The separation of pulp potatoe residues, plastic waste water or sewage sludge has already been approved.

What challenge there is to cope, we are providing the solutions!