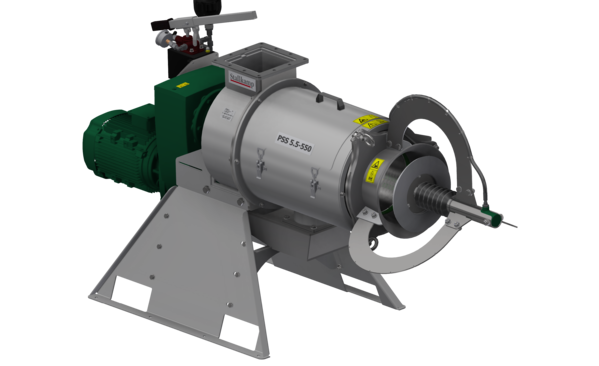

Our PSS 4/5.5-500 at a glance

Press screw separator consists of:

- Stainless steel separator

- Press screw right-and double-standard stainless steel with tungsten carbide plated

- Stainless steel screen basket with defined gap

- Drive motor 400/690V, 50 Hz, 4,0 kW, 28 rpm.

- Temperature of the separated medium up to a max. of 50 °C

The mobile unit large consists of:

- basic machine PSS 4-550 or PSS 5.5-550

- supply and discharge pump

- receiver tank 0,85 m³ with level indicator

- hopper 0,85 m³ with level indicator

- control cabinet for controlling the separator and the both rotary lobe pumps

The mobile unit small consists of:

- basic machine PSS 4-550 or PSS 5.5-550

- feeding pump

- hopper 0,85 m³ with level indicator

- control cabinet for controlling the separator and the both rotary lobe pumps

Agriculture

- Separation of cow, cattle and pig manure

- For the production of organic bedding material in cow sheds

Biogas plants

- Separation of digestate and fementation residues after the digestion process

Industry

- Food industry: Separating vegetable waste, for example potato sludge

- Slaughterhouses: Separation of rumen contents

- Distilleries: Separation of the mash

- Waste water treatment: Separation of sludge

- Increases dry matter

- Speeds up cleaning/service process

- Quicker operational readiness since the plug does not have to be established from foreign material

- Due to the even force distribution of the ball head on the fixed material, reliable separator operation occurs

- Required degree of dry matter during running operations effortlessly modifiable and, thanks to the manometer display, effortlessly reproducible

- Separator PSS 4-550-M-1301 with hydraulic cylinder head

- Motor 4 kW, 28 U/min

- Manual hydraulic pump with diaphragm accumulator and manometer for cylinder head

- Inlet

- Hydraulic dylinder head pivoted for maintenance

- Stainless steel sieve basket, optional reinforced

- Armored auger

- Discontinued 3” internal thread