20.01.2020 - Construction of mega biogas plant in Denmark starts

In Hojslev near Viborg (Middle of Jutland) the construction of a mega biogas plant has started. Stallkamp produces all digesters with according pump and mixing technology.

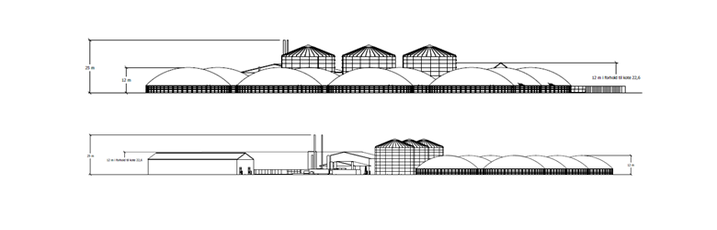

Client of the project is Lundsby Biogas ApS, whereas, the construction is realised by the Danish Stallkamp distributor Biogas Teknik A/S. The biogas plant covers 14 digesters made from stainless steel. Three of them are tall fermenters with stainless steel roof and the other 11 will be built with a gas-tight double membrane roof. The following tanks are supplied by Stallkamp:

- 3 tall fermenters Ø 23m height 20m

- 6 digester Ø 35m height 10m

- 3 digester Ø 31m height 10m

- 2 digester Ø15m height 6m

Outline of the Danish mega biogas plant:

Start of construction at April first

Since the 1st of April the installation teams are on site and the open space turns into a modern renewable energy park where sustainable stainless steel tanks grow from scratch.

Renewable energy from manure und waste

The plant will treat about 400,000 tons of biomass every year which will lead to an output of 33.6 Mio m³ upgrades biogas. The maximum capacity of the plant is 600,000 tons of biomass and a yield of 40 Mio m³ upgrades biogas meaning that the plant still has capacity for growth. The input of the plant is mainly pig and cow manure, but other substrates like bedding material, glycerin, corn and grassilage and waste from the food industry e.g. potatoe and olives are digested in the new biogas plant. It is planned to bring gas to grid in December 2019.

Experienced with similar projects before

This project in Hojslev is definitely a lighthouse project causing attention in the whole industry. But in 2018, Stallkamp already built quite a huge project, the biggest glycerin tank in Denmark with 4.500m³. The digester was integrated into an existing biogas plant. The previous project provided important know-how for Stallkamp.

Why stainless steel for tanks and digesters?

Stainless steel tanks from Stallkamp are very durable because of its resistance to corrosion. Due to its chrome content, a razor-thin, chemically resistant passive layer is formed at the surface in connection with the oxygen in the air or water. If the passive layer is damaged due to external influences, it re-builds itself from the matrix of the stainless steel. In contrast with other materials or material combinations, rust-free stainless steel can be fully recycled without any issues after use

The video on our Youtube Channel shows the progress of the project (September 2019).

Update turn of the year

At the end of 2019 the first CST digester (continuous stirred tank) reached its full height at 20m. In 2020 the central stirring system for the first CST was installed. The stirring parts were stored inside of the tank and assembled. By help of a crane the stirring system was lifted up to the top. The motor for the mixer was positioned outside the tank on top of the roof. The next step will be the isolation and cladding of the whole digester. Thus the first filling of the tank can be sheduled (Information from 20.01.2020).

At the same time, the progress of the other two similar CST digesters is going on. The stainless steel roof of the second CST is finished so that the tank can grow ring by ring in the following weeks. The construction of the roof for the third CST already started.

Updates of the project are following.

https://www.stallkamp.de/en/company/news/584-biogas-plant-with-14-digesters-in-construction#sigProIdb80244f7d6